It is crucial to select tools used at a workshop for different machining applications analyzing the work requirement and considering the features. The work piece gets categorized either under ferrous or non-ferrous materials. Characteristics of the tools largely affect the machining works and productivity. Thus, intending to achieve a high precision finish, you need to select the right set of tools. Make sure to analyze and learn about the specification and work requirements before using any tool for machining products.

Select the right tool that will serve you in the best way

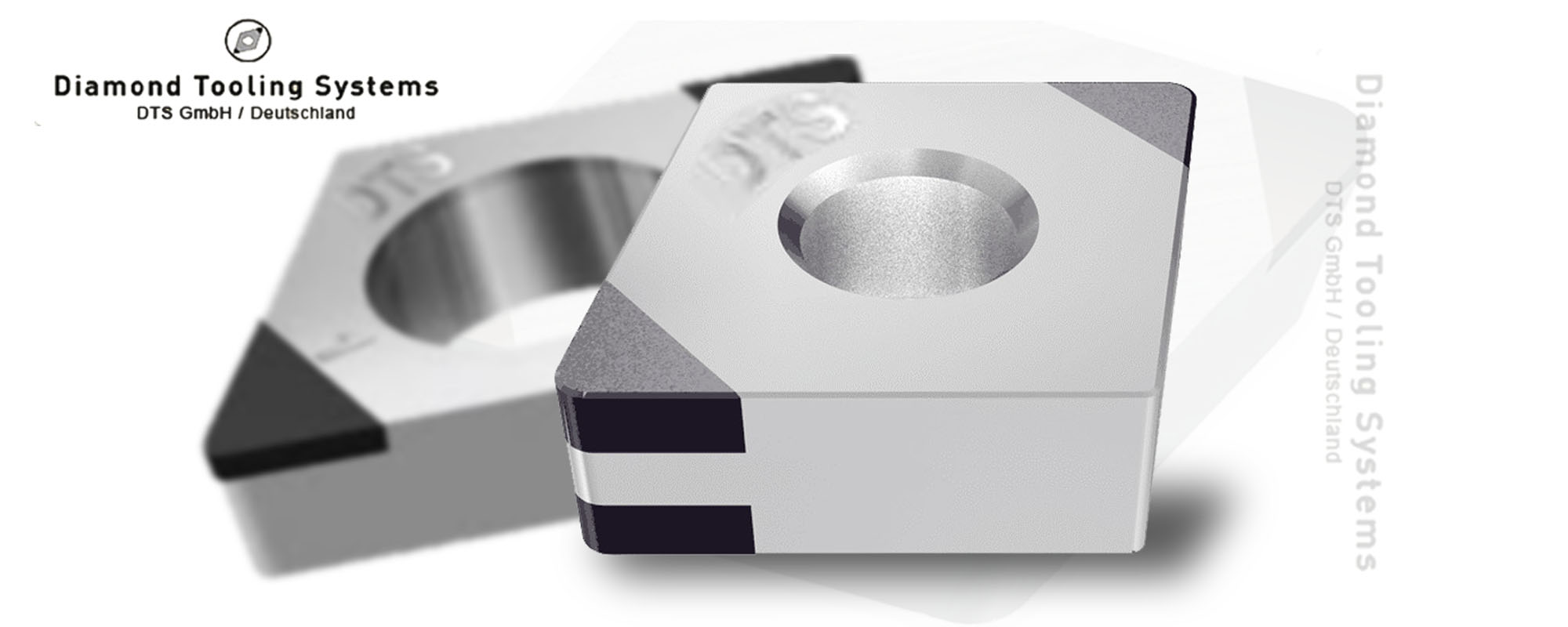

If you are searching for the best tool for cutting hard and brittle materials like glasses, composites or ceramics, you can use Diamant werkzeuge. Diamond is well-known for its hard properties. However, the integrated features of diamond tools make it expensive. Such tools ensure ultra-precision machining of non-ferrous materials with a guarantee on an excellent finish. For its excellent properties, these tools get extensively used for different machining operations like grooving, milling, turning, boring and facing. Make sure to purchase high-precision tools that will serve you in the best way.

You need to select the right tool for Hochglanz fräsen. Collect maximum information about the tool and its efficiency before purchasing. Such machining products get designed with high-precision and meet the international standards of tool designing. You need to select the machining products with an extended lifespan. Using high-standard tools you can accelerate productivity ensuring flawless machining.

Diamond Tooling Systems is the hub of high-standard products

Diamond Tooling Systems is a hub of high-standard tools used extensively at workshops for different machining operations. Visit www.diamond-toolingsystems.com and search for the tools you need at your workshop. The manufacturer designs high-end products with high durability. The products ensure flawless machining works with less time consumption. You can find a wide stock of products for your workshop at a cheap price range.