Are you searching for the best tool for turning titan or turning Inconel? Did you research which could be the best cutting equipment for your workshop?

Yes! The cutting tools used in the workshops, play a vital role in scaling up the productivity. Selecting the right set of tools help in reducing the labor, time and costs. Don’t you want to keep the machines and work uninterrupted? Select high-grade tools manufactured following the international industrial standards and achieve the targets of maintaining and multiplying the work flow without any interruptions!

Select the right set of tool and scale up the productivity of your workshop

Whether you are searching for the best tool for milling graphite or milling titan, you must select the right and appropriate one! The cutting equipment gets designed, developed and manufactured from different materials. But, certain materials react with harder materials used for the cutting tools. You must consider the essential factors and judge the right one in your workshop.

Cutting equipment from the second-hardest material is the best choice for ferrous materials

You can’t use the ordinary tools to cut hard materials. However, it is easier and more effective to cut harder materials with cutting tools of harder materials. Cubic Boron Nitride is the first choice for the tool manufacturers. It is the second hardest known material possessing high thermal conductivity power and being extremely hard; these are highly resistant to wear. CBN Tools are popular in the workshops and industrial spaces.

Cubic Boron Nitride is very hard the manufacturers use it to produce tools of high precision. The material is resistant to chemical reactions and also is abrasion resistant. This material is the best option for cutting ferrous materials. Possessing such excellent features and delivering effective results, the price of Cubic Boron Nitride is high. As Cubic Boron Nitride is expensive, the manufacturers opt for manufacturing its alternative. Tools with CBN Coating are gaining popularity. The special coating of the second hardest material on any tool material scales up its hardness and enhances its durability, strength and wear resistant power.

If you need a tool for machining automotive components, CBN insert would be the best choice as it excellent works for hard-to-soft rough machining. It removes the hardened layer from the surface of the component. With this tool, you don’t require multiple cuts. A CBN insert with chip breaker maintains the single cut strategy and scales up the productivity.

The efficiency of coated tools

The CVD Coated tools reduce the cutting force and tool wear as it distributes the layer consistently. It is a popular coating method used for manufacturing tools for milling carbide, including different cutting equipment for plastics. CVD Coating ensures excellent resistance of the equipment.

If you want the best tool for cutting non-ferrous materials, Diamond Coating tools will deliver you the best solutions! The diamond coated equipment balances the heat from the cutting edge that extends the tool’s life. Machining non-metallic and non-ferrous materials are effective with the diamond coated equipment.

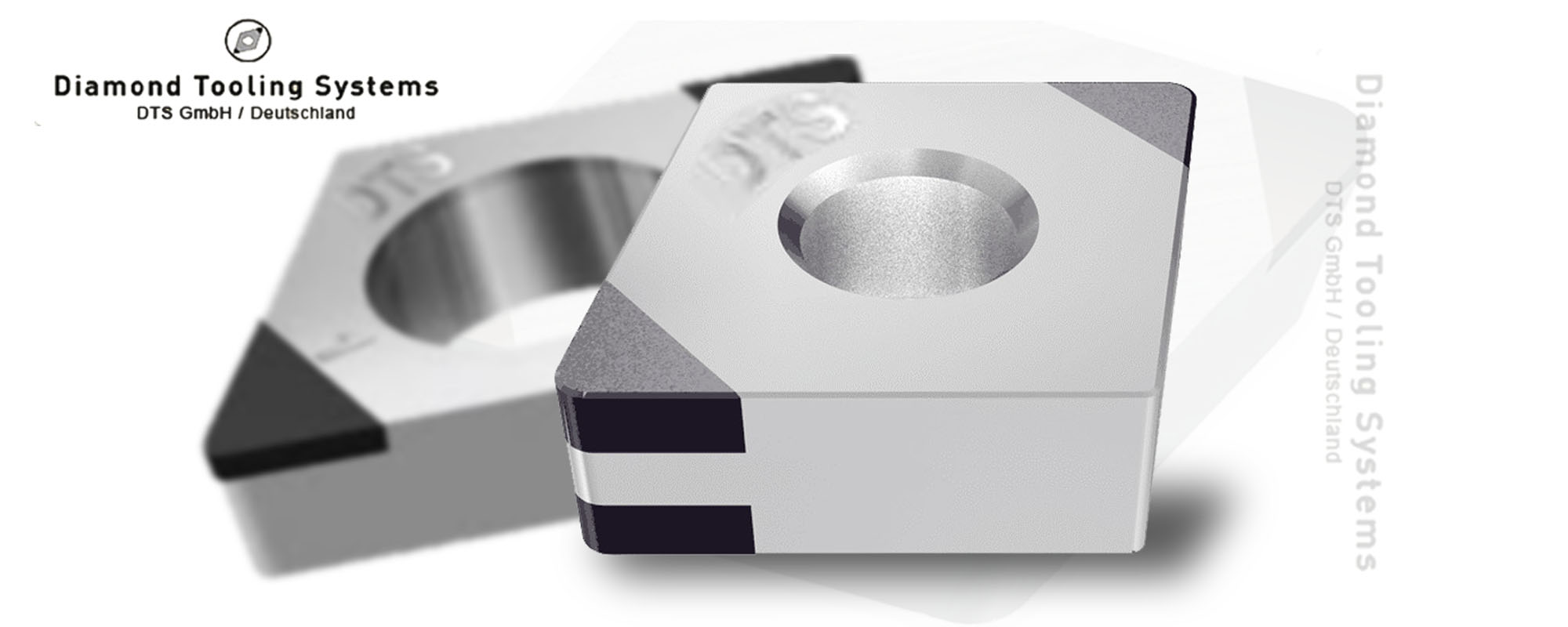

Purchase the appropriate set of equipment @ Diamond Tooling Systems

Apart from selecting the right set of tools considering the material to-be-cut, turn or grind, you need to give high emphasis on the grade. Diamond Tooling Systems manufactures and markets cutting tools of high grades. It designs and develops milling Inconel, turning carbide and several other cutting tools appropriate for different industrial spaces. It manufactures the products following and maintaining the international industrial standards. Purchase the products at the best price range in the industry. Visit http://www.diamond-toolingsystems.com and select the cutting tools and equipment appropriate for your workshop!