Every industry wants to keep the expenses of processing minimum possible while manufacturing industrial parts. At the same time, they want to ensure zero compromises in terms of quality. To fulfill both the use of diamond coating cutting tools has significantly grown. The same is also the reason behind the greater usage of carbide cutting tools.

Pre-treatments improving the process

Maintaining the proper bonding of diamond coating used to be complex. It used to be challenging specifically while making the processing of featherweight materials. However, with needful pre-treatment, things have indeed improved in a noteworthy fashion. Adhesion of CVD coating with carbide has improved to a great extent. This is said to be the outcome of a combination of addressing all the key aspects that come on the way of adhesion of the coating.

Maintaining the perfect blend

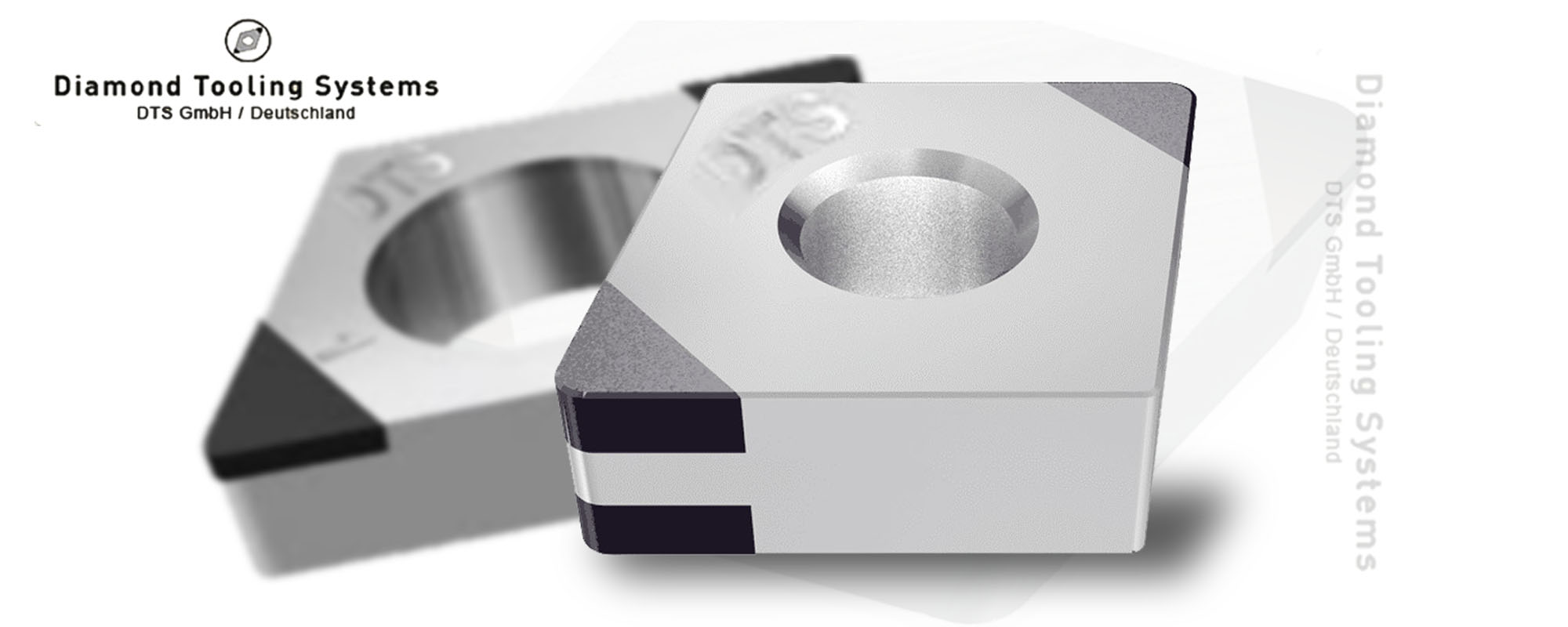

In present times, cemented carbide is hugely applied with the cutting tools of industries. It is said to be the outcome of a perfect blend of tungsten carbide with cobalt. The role of carbide is basically to provide the toughness. On the other hand, cobalt provides needful cohesiveness or adhesiveness. This is the reason that CVD diamond coating is known for its greater toughness and the ability of resistance. Best result can be pretty much guaranteed upon keeping the combinations right.

To ensure that the adhesive agent reacts less with the diamond already formed, the same is removed through a strategic chemical process. It is often called as the wet chemical process. The early treatments of such are always recommended to be done by the experts only as there remains the risk of posterior zones to get leaky and affect the rigidity. However, upon maintaining the pre-treatments perfect, the irregularities often witnessed while cutting can be greatly avoided. All that one needs to ensure is to use only the homogenous materials.