Electron Beam Evaporation or (EB) vanishing is a form of physical vapor testimony, where a block of the material (source) to be dumped is heated to the point where it flinches to boil and evaporate. Then it is permissible to condense on the substrate. This procedure takes place inside a vacuum chamber, with a thin layer of the terminal material. A thickness of less than one micrometre is commonly called a thin film while a thickness greater than one micrometre is termed as Thin Film Coating.

Electron Beam (eb) evaporation coatings procedure falls into a larger category of procedure identified as Physical Vapor Deposition (PVD). Deposition procedures are used to release a material from a source and transmission that material to a substrate, starting a thin film coating. PVD procedures are normally used for the deposition of metals; as they can be performed at lower procedure risk and cheaper in regards to materials cost than Chemical Vapor Deposition (CVD).

The electron beam (eb) evaporation coatings process usually comprises the following components:

- Electron Beam Evaporation Gun

- A System Controller

- Power Supply

- Crucibles for the evaporation material

- Materials for Evaporation

- Material to be coated

Thin film deposition is a procedure carried out in optics industries to convey the desired reflective assets while, in the aerospace industry to form thermal and CVD coatings to protect the surfaces against corrosive environments, in semiconductor industry to grow electronic materials and elsewhere in industry to modify surfaces to have a variety of shapes. Deposition procedure can be largely classified into PVD and chemical vapor deposition (CVD).

When the vapor basis is from a liquid or solid sensible the process is called physical vapor deposition (PVD). When the source is from a chemical vapor the process is called low pressure chemical vapor deposition or, if in a plasma, plasma enhanced CVD or „plasma assisted CVD“.

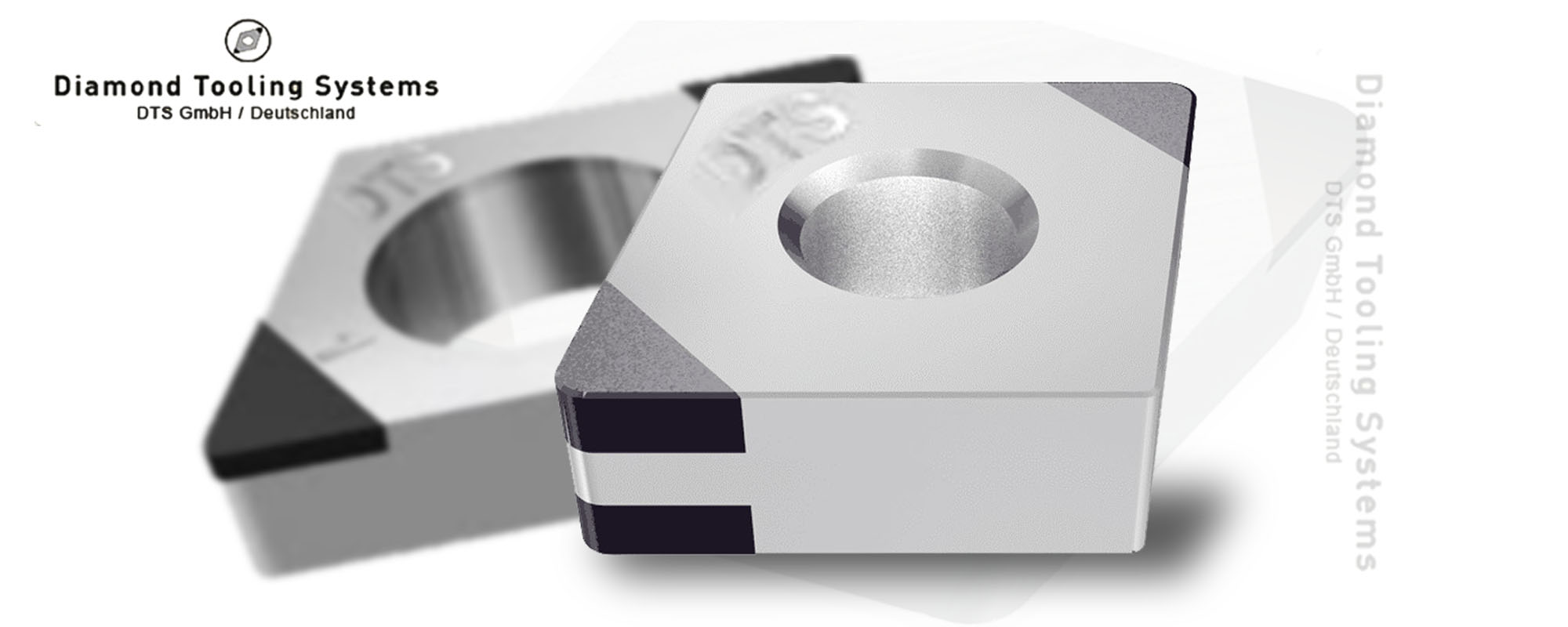

Electron beam evaporation is a normally used procedure for coating lenses and filters with anti-reflection, scratch-resistant or other specialized coatings. The process is also commonly used for CBN insert with chip breaker and resistor films on electronic components.